Context

Five weeks before Paris Fashion Week and only a few days after your Mission Briefing, Category 4 cyclone Aphrodite roars ashore near Chittagong, Bangladesh. News reports show drone footage of swollen rivers swallowing the road to Gazipur; the normally bustling port is a muddy expanse of toppled containers.

Inside STG’s factory, videos filmed on mobile phones show workers wading through waist-deep water, fabric bolts floating like debris. The power grid is failing; you hear the hum of generators punctuated by distant thunder. Raw materials for the EcoLux collection—peace silk and organic cotton—are stranded on ships anchored offshore, unable to berth at Chittagong port. The smell of damp textiles hangs in the air.

Gazipur’s full recovery timeline remains uncertain, but pressure is mounting to either reroute production or hold the line.

Chittagong Port, Bangladesh (slide left/right)

Task

Choose how STG should respond to the cyclone‑induced production halt, balancing worker safety and community support against the need to deliver the collection on time.

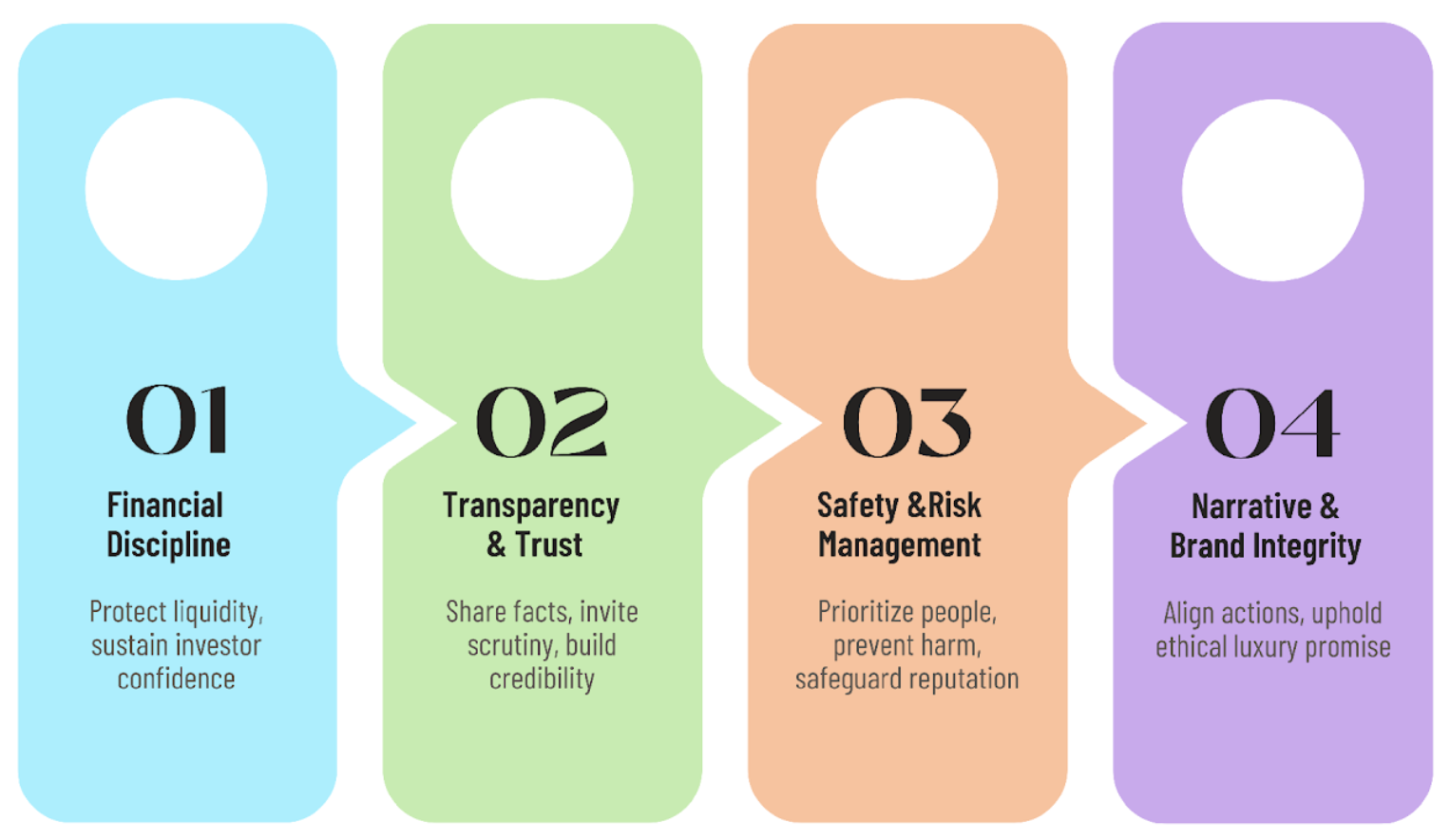

Options

Explore the strategic response options available to STG following the flooding in Gazipur. Select a tab to read each option’s approach, advantages, and disadvantages.

- Option 1

- Option 2

- Option 3

- Option 4

- Option 5

- Option 6

Option 1: Vietnam Capacity Surge

Shift the remaining production to STG’s secondary facility in Da Nang, Vietnam. Charter cargo flights to transport materials and partially finished garments from Bangladesh to Vietnam. Delay some non-critical product lines to free capacity.

Advantages

- Quickly restores production and mitigates further flood risk.

- Leverages Vietnam’s stable infrastructure and skilled workforce.

Disadvantages

- High transportation and overtime costs, including charter flights and premium surge labor.

- Potential overwork for Vietnamese staff.

- May strain relations with Bangladeshi workers who could feel abandoned.

- Flight corridor restrictions may delay or complicate cargo transport from Bangladesh.

Option 2: Rebuild then Reveal

Temporarily suspend production and invest in rebuilding the Gazipur facility. Provide emergency relief to workers, including medical care, food and temporary housing. Negotiate with Paris Fashion Week organisers to reschedule STG’s runway slot for a later date.

Advantages

- Demonstrates strong commitment to employee welfare and community support.

- Strengthens brand loyalty and may secure favourable media coverage.

Disadvantages

- Risk of losing momentum during the fashion calendar.

- Potential financial penalties for missing deadlines.

- Investors may question management’s ability to deliver.

- Recovery timeline remains uncertain and weather-dependent, making planning volatile.

Option 3: The Sky Bridge

Airlift raw materials from warehouses in India and Thailand directly to Milan and Paris. Redirect skilled artisans from Prato to produce critical pieces. Offer bonuses to Bangladeshi workers who can resume operations quickly.

Advantages

- Keeps the collection on schedule and maintains brand visibility.

- Shows operational agility under pressure.

Disadvantages

- Significantly higher carbon footprint and logistics costs.

- May compromise STG’s sustainability messaging.

- Could set a precedent for future airfreight reliance.

Option 4: Capsule Couture Pivot

Reduce the number of looks in the EcoLux line by focusing on high-impact, versatile pieces that can be finished with available materials. Shift marketing to emphasise exclusivity and bespoke craftsmanship.

Advantages

- Easier to manage with limited production capacity.

- Can create a “limited-edition” aura that drives desire.

Disadvantages

- Reduced revenue potential.

- May frustrate buyers expecting a full collection.

- Could misalign with the original design vision.

Option 5: NGO Relief Weave

Collaborate with humanitarian organisations and local cooperatives to provide aid and temporary production space. Mobilise STG’s sustainability budget to fund emergency generators, water purification units and mobile clinics. Jointly develop a community co-production model where small workshops contribute to finishing tasks.

Advantages

- Protects workers and builds goodwill.

- Offers innovative production resilience.

- Aligns strongly with STG’s social mission.

Disadvantages

- Coordination complexity and potential variability in product quality.

- Slower production pace compared with a single factory.

Option 6: Quiet Channel Recovery

Temporarily engage a known subcontractor in Pakistan to complete 10–15 key EcoLux looks. The facility has prior ties to STG but isn’t yet certified under its new ethical standards; disclosure would be delayed until post-inspection to avoid disruption.

Advantages

- Delivers a portion of the collection on time.

- Preserves runway visibility and the creative vision.

- Demonstrates crisis responsiveness under pressure.

Disadvantages

- Subcontractor is not fully compliant with new transparency standards.

- Risk of reputational damage if external audits or media flag the gap.

- May undermine trust with NGOs, investors, and internal ethics teams if later revealed.

Decision

After carefully reviewing the options above, your team must now choose the response strategy that best aligns with STG’s objectives and values. Select one option below to record your team's decision with 2 mins (or less) remaining.